TEC® Enables Solid Subfloors to Support Fitness Club’s Design Concepts

Giving a facility owner a positive outcome on new construction or a remodeling project requires trust-based relationships. Itasca, IL-based flooring contractor Diverzify has earned the trust of Chicago’s Midtown Athletic Clubs by providing reliable expertise and materials on floor construction and renovation projects over several decades. When Midtown planned to renovate three of its facilities this year, its facilities team knew Diverzify would come through once again.

“We wanted to recreate the facilities and give them the new Midtown brand,” notes Trish Stieglitz, Midtown’s vice president of development and facilities. Flat, even, structurally sound subfloors supporting several new exercise and activity areas are not minor considerations in Midtown’s efforts to enhance its clubs in the Chicago and Rochester, NY markets. You might say solid subfloors support the brand just as much as they support tile and flooring materials. Midtown understands that real floor quality, and people’s perception of quality, go hand in hand.

Renovations followed Chicago model

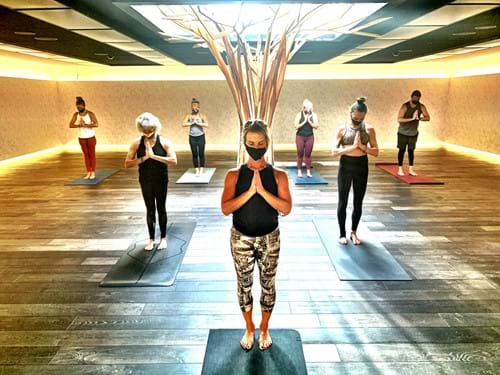

In 1970, Midtown opened its first Chicago tennis club facility, one that would hold the distinction of largest indoor tennis club in the world for decades to come. In 2013, through eminent domain, the City of Chicago took a large portion of the Midtown facility’s property for a new roadway project. Midtown immediately started to reimagine its flagship club and in 2017 completed an $80 million expansion of the remaining property. Now a six-story, 575,000-square-foot boutique tennis and fitness facility, Midtown Athletic Club Chicago features many distinctly themed fitness areas including a Ride (spin) Studio, boxing studio named “Everybody Fights”, group fitness studio named “The Theater”, a Pilates and yoga studio called “Samadhi”, incorporating two full-scale tree structures to obscure the steel columns, four swimming pools and a 55-room hotel on the fourth and fifth floors. “You feel like you’re entering a new place every time you walk into a different studio,” notes Stieglitz.

The new concept became so popular that Midtown maximized capacity soon after opening. Midtown’s leadership wanted to replicate much of the successful new concepts at some of its eight other U.S. and Canadian facilities. “We knew we created something really special and we took it on a “road show” to our Bannockburn, Illinois and Rochester, New York facilities,” Stieglitz says. In late 2019, Midtown began renovating those facilities and then incorporated many of the Chicago design concepts into its Willowbrook, IL facility, phasing construction improvements while the clubs remained open. When the COVID-19 pandemic forced the facilities to close in early 2020, Midtown was able to expedite some of the renovations.

Trusted partners provide expertise

In late 2019, Stieglitz spoke with her longtime flooring contractor David Zmijewski, founder of Mr. David’s Flooring International—now Diverzify—about the renovations. As was the case on most of Midtown’s flooring projects going back many years, Zmijewski worked with Ron Loffredo, OEM technical advisor at H.B. Fuller, to identify the right subflooring materials.

The Bannockburn facility reopened in August with the renovations nearly complete. The Rochester facility reopened in October with most of the renovations complete. At the latter facility, Midtown converted several tennis courts into fitness spaces with artificial turf and luxury vinyl tile (LVT) floor coverings. Those floors needed a subfloor material installed on the adhesive that remained after carpet was removed.

Several other TEC® products were used for the renovated floors under the new exercise areas in the Rochester facility. TEC® LiquiDam EZ™ Moisture Mitigation was applied on freshly placed cement two days prior to the installation of the LVP on the facility’s second level. TEC® Feather Edge™ is a rapid-setting cement-based compound, that was used to skim coat, smooth and level irregularities from featheredge up to ½ inch (12 mm). Finally, TEC® TrowelFast™ Premium Vinyl Flooring Adhesive was chosen for its suitability for vinyl floors that sustain heavy rolling loads.

Zmijewski and Loffredo proposed TEC® floor preparation solutions to handle the job. Loffredo personally supervised the application of TEC® Multipurpose Primer and next generation Level Set 500 HF Self Leveling Underlayment.

At the Midtown Athletic Club in Willowbrook, IL, an existing multitude of floor coverings over an asphalt surface of four tennis courts was also reimagined. One of the tennis courts, converted many years earlier into a regulation basketball court, was strategically disassembled and relocated to a new space as “The Theater”. All courts were then finished as personal training space, weight training and cardio fitness with artificial turf, luxury vinyl plank (LVP) and recycled rubber floorcoverings.

The new surfaces needed to be level, even though each floor material was dimensionally different and removing the old carpet adhesive from the asphalt was impossible, according to Stieglitz. Additionally, the fitness equipment floors needed to stand up to constant pressure from cardio machines and continuous impact from dropped heavy weights. “In the fitness industry, ‘use is abuse,’ as the saying goes,” says Stieglitz.

Rather than grinding off the glue and compromising the asphalt surface any further, Midtown had plywood installed on the existing tennis court surface. As at the Rochester facility, TEC® Multipurpose Primer and Level Set® 500 HF Self Leveling Underlayment were used to even the transitions from the different flooring materials. “It turned into an easy and fast project,” Stieglitz says.

Desired outcome once again

Stieglitz and Midtown got the desired outcome by working with longtime partners Zmijewski and Loffredo. “Nobody else would ever see his product or understand how it performs, but I do,” Stieglitz says of the subfloors that used TEC® floor preparation solutions. “I don’t need to replace it or have it repaired, like I would if I used any other product. While it’s a part of the floor that the public never sees, it’s one of the most important parts of the project.

When I have Ron on my project and I have his opinion, expertise and products, I walk away after it’s done and I don’t worry about it anymore,” Stieglitz continues. “I have never had a problem with the subfloors I’ve put down. I am keen on the fact that I am always going to get a really good product out of them no matter what. They are not going to steer me wrong—they care about providing a good product and they are proud of what they do. It is absolutely a good working relationship and one I rely on time and again.”