A “Cut Above the Rest”: Bridge concrete saw cut joints with TEC® HydraFlex™ Crack Isolation and Waterproofing Membrane

It’s not if concrete will crack. It’s when it cracks and if your tile is bonded to the cracking concrete, what happens? That will crack too.

One of the pains of specifying and installing tile over concrete is figuring out the proper way to keep tile intact despite substrate cracking due to shrinkage. Unfortunately, many installation guidelines for crack isolation membranes result in numerous cuts in the middle of the tiles that can detract from the overall aesthetics of the floor. (See Figure 1). What do you do, as a contractor or specifier?

TEC® HydraFlex™ Waterproofing / Crack Isolation Membrane is the solution.

Most Division 09 30 00 tile setting specifications list crack isolation and/or waterproofing membranes that can meet ANSI A118.12 specifications for crack isolation and ANSI A118.10 for waterproofing.

However, only one liquid-applied membrane can bridge saw cut / control joints: TEC HydraFlex.

Not only does TEC HydraFlex exceed both ANSI crack isolation and waterproofing specifications, it is the only liquid applied, crack isolation membrane that can bridge saw cut/control joints.

What does that mean?

Movement joints in concrete allow the concrete to move without restraint; they control where the movement manifests to avoid random cracking in finish materials or to allow for expansion and contraction in the concrete. Types of concrete movement joints include expansion joints, cold joints, and control (or saw cut) joints.

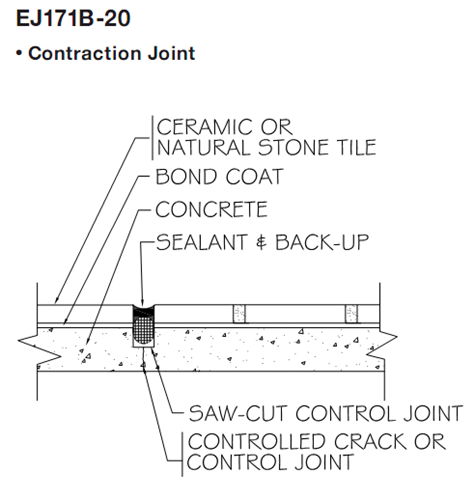

Expansion joints and cold/control joints are installed in concrete to allow for natural expansion and contraction with temperature changes. These joints must be honored through the tile installation so that the entire system can expand and contract with temperature changes, as outlined in TCNA EJ171.

Control/saw cut joints are designed to force the concrete to crack along the saw cut during the curing process. As moisture leaves the concrete it will shrink, causing it to crack. These cracks are not expansion joints. Instead, they are put there to control where the concrete shrinkage cracks occur.

Most competitive brands of liquid applied crack isolation membranes are not recommended to bridge concrete saw cut joints. This results in the contractor being required to install “soft joints’ directly above the saw cut joint as is written in TCNA EJ171**. [See Figure 1]

[Figure 1]

Most crack isolation membranes on the market come with warnings on their datasheet, like:

“Provide for expansion and control joints as specified per TCNA Method EJ171”

“Do not use to relocate tile joints over saw cuts/control joints in concrete slabs"

“Do not use to bridge dynamic joints such as cold, control or expansion joints”

A “soft joint” is also referred to as an expansion or movement joint in the tile assembly. As described in detail in EJ171 [See Figure 2] in the TCNA Handbook, in place of grout, the joint is filled with a sealant.

[Figure 2]

What does this “soft joint” in the tile layout, that is directly above the saw cut joint, look like from above? [See Figure 3]

[Figure 3]

TEC HydraFlex Waterproofing Crack Isolation Membrane is the only liquid-applied, crack isolation membrane, that allows the installer to bridge the saw-cut joints in concrete. When applied in full coverage using TCNA F125-Full installation method, this allows the installer the choice NOT to insert soft joints directly above or near saw cut joints as all competitive products require, meaning no cuts are required through the tile due to the saw-cut joint.

TEC HydraFlex allows more freedom for more aesthetically pleasing tile layouts and less soft joints when used in full coverage.

Other features of TEC HydraFlex

Double the crack size protection versus competitive brands: offers the choice for 1/4” maximum in-plane cracks when applied at 50 mils wet-film thickness (WFT).

10-Year Limited Product Warranty when most other brands only offer 1-year or six months.

Half the installation time for 1/8” crack applications as only 25 mil WFT is required in one coat. Competitive brands require two coats to meet ANSI A118.12.

For technical assistance with our products: 1-800-TEC-9023 (1-800-832-9023); Mon-Fri 7:00 a.m. — 6:00 p.m. CST

If you are a contractor, contact Heather Ruhl, North-American Training Manager at [email protected] or your local Technical Sales Pro for more information.

**TCNA is Tile Council of North America. “EJ 171” is the one installation recommendation found in the TCNA Handbook on Movement Joints in tile assemblies.

TEC® is a registered trademark of TEC Specialty Products LLC. Hydraflex is a trademark of TEC Specialty Products LLC.

HydraFlex installation images provided by Welch Tile & Marble, Kent City, MI